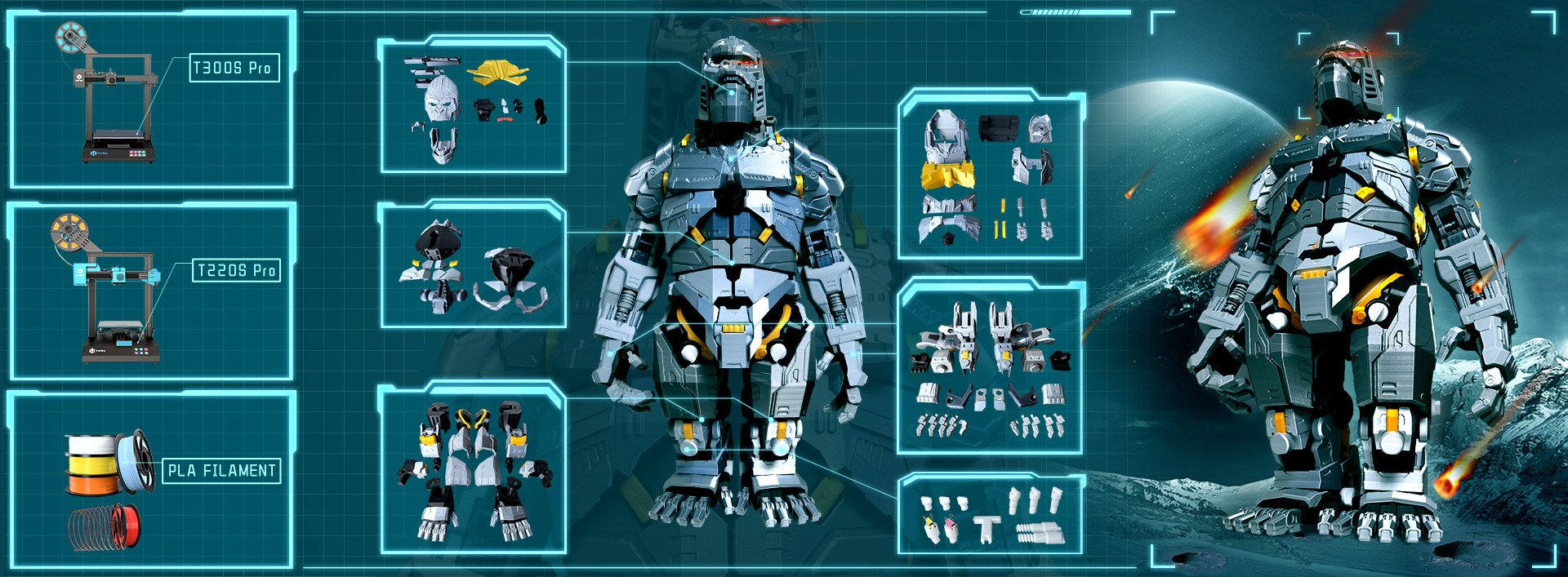

Fused Deposition Modeling (FDM) is one of the most popular 3D printing technology that widely used in manufacturing, medicine, architecture, arts and crafts, education and design due to its technical advantages such as rapid prototyping, more cost-effective manufacturing process, flexibility to create anything that fits the build volume, detailed and intricate parts manufacturing and less post-processing, to name a few. Now we are using TronHoo’s FDM 3D printer T300S Pro and PLA filament to print a Giant Mecha King Kong.

Let’s go through the whole process to discover the fun of 3D printing.

Firstly, downloading the model file that you like from 3D printing service platforms such as MakerBot Thingiverse, My MiniFactory and Cults. In this case, a mecha King Kong (creator: toymakr3d) is selected due to its detailed and intricate structure, it is a great example to test the performance of a FDM 3D printer. In addition, this mecha King Kong model has about 80 parts, which can be scale up to fit the large build volume of T300S Pro, and finally assembled into a giant model.

Secondly, slicing the different parts of model into suitable layers, according to the principles of increasing the adhesive surface of the model to reduce supports as well as increasing printing speed and optimizing printing effect by slicing software such as Ultimaker Cura and Simplify3D. In this case, all 80 parts are sliced accordingly and properly.

Thirdly, copy the sliced 3D model files into the card and insert it into the TronHoo’s T300S Pro and power it on. The printer supports fast heat-up the printing bed without waiting. The printer also supports automatically leveling. The T300S Pro has large build volume up to 300*300*400mm, available for big ideas. During the printing, the function of filament run-out detection enables continuous printing. There is no need to worry about power failure, the function of power outage protection allows the printing to resume after power-off. Plus, the German imported motor drive system, effective denoising, makes the whole printing without disturbance.

After two weeks of printing on five printers, all the parts of mecha King Kong are completed and assembled. In this case, the whole process is pretty smooth and interesting. More importantly, we printed a unique, huge and extremely playable mecha King Kong.

Post time: Dec-16-2021