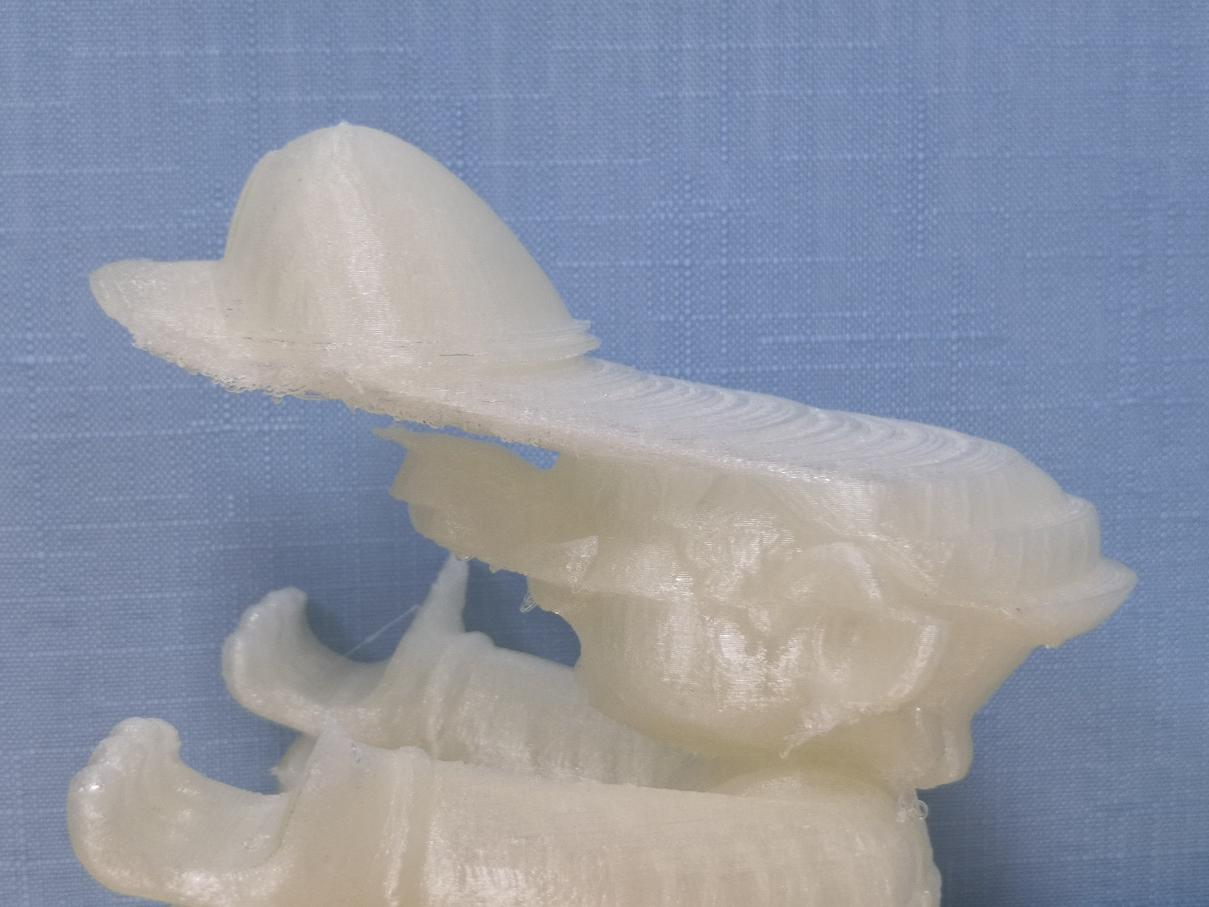

WHAT’S THE ISSUE?

During printing, the filament did not stack up in the original direction, and the layers shifted or leaned. As a result, a part of the model was tilted to one side or the entire part shifted.

POSSIBLE CAUSES

∙ Being Knocked During Printing

∙ Printer Losing Alignment

∙ Upper Layers Warping

TROUBLESHOOTING TIPS

Being Knocked During Printing

Even small shake during the printing process will affect the quality of the print.

CHECK THE PRINTER HAS A STABLE BASE

Make sure that you have placed the printer on a stable base to avoid collision, shaking or shocking. A heavier table can effectively reduce the impact of shaking.

CHECK THE PRINT BED IS SECURE

Due to shipping or other factors, the print bed may be loose. In addition, for some detachable print bed that are fixed by screws, the print bed will become unstable if the screws are loose. Therefore, you need to check that the screws of the print bed are tightened before printing so that the print bed wouldn’t slip or move.

Printer Losing Alignment

If there has any loosen component or the movement of the axes are not smooth, the problem about layers shifting and leaning will happen.

CHECK X- AND Y-AXIS

If the model is shifted or leaned to the left or right, there may be a problem with the X axis of the printer. If it is shifted or leaned forward or backward, there may be a problem with the Y axis.

CHECK THE BELTS

When the belt rubs against the printer or hits an obstacle, the movement will meet resistance, causing the model to shift or lean. Tighten the belt to ensure that it does not rub against the sides of the printer or other components. At the same time, make sure that the teeth of the belt are aligned with the wheel, otherwise printing trouble will occur

CHECK ROD PULLEYS

If there are too much pressure between the pulley and the guide rail, the movement of the pulley will stand excessive friction. As well as the movement of the guide rail if there has obstacles, and they will cause shifting and leaning. In this case, properly loosening the eccentric spacer on the pulley to reduce the pressure between the pulley and the guide rail, and adding lubricating oil to make pulley move smoother. Pay attention to clean the guide rail to prevent objects from hindering the pulley.

TIGHTEN THE STEPPER MOTOR and coupling

If the synchronous wheel or coupling of the stepper motor is loose, it will cause the motor out of sync with the movement of the axis. Tighten the screws of the synchronization wheel or coupling on the stepper motor.

CHECK RAIL GUID NOT BENT

After turning off the power, move the nozzle, print bed and other axes. If you feel a resistance, that means the guide rail may be deformed. This will affect the smooth movement of the axis and cause the model shift or lean.

After detecting the problem, use an Allen wrench to tighten the screws of the coupling connected to the stepper motor.

Upper Layers Warping

If the upper layer of the print is warped, the warped part will hinder the movement of the nozzle. Then the model will shift and even be pushed away from the print bed if seriously.

decrease the fan speed

If the model cools down too fast, warping will easy to happen. Slightly reduce the fan speed to see if the problem can be solved.

Post time: Dec-31-2020