Blog

-

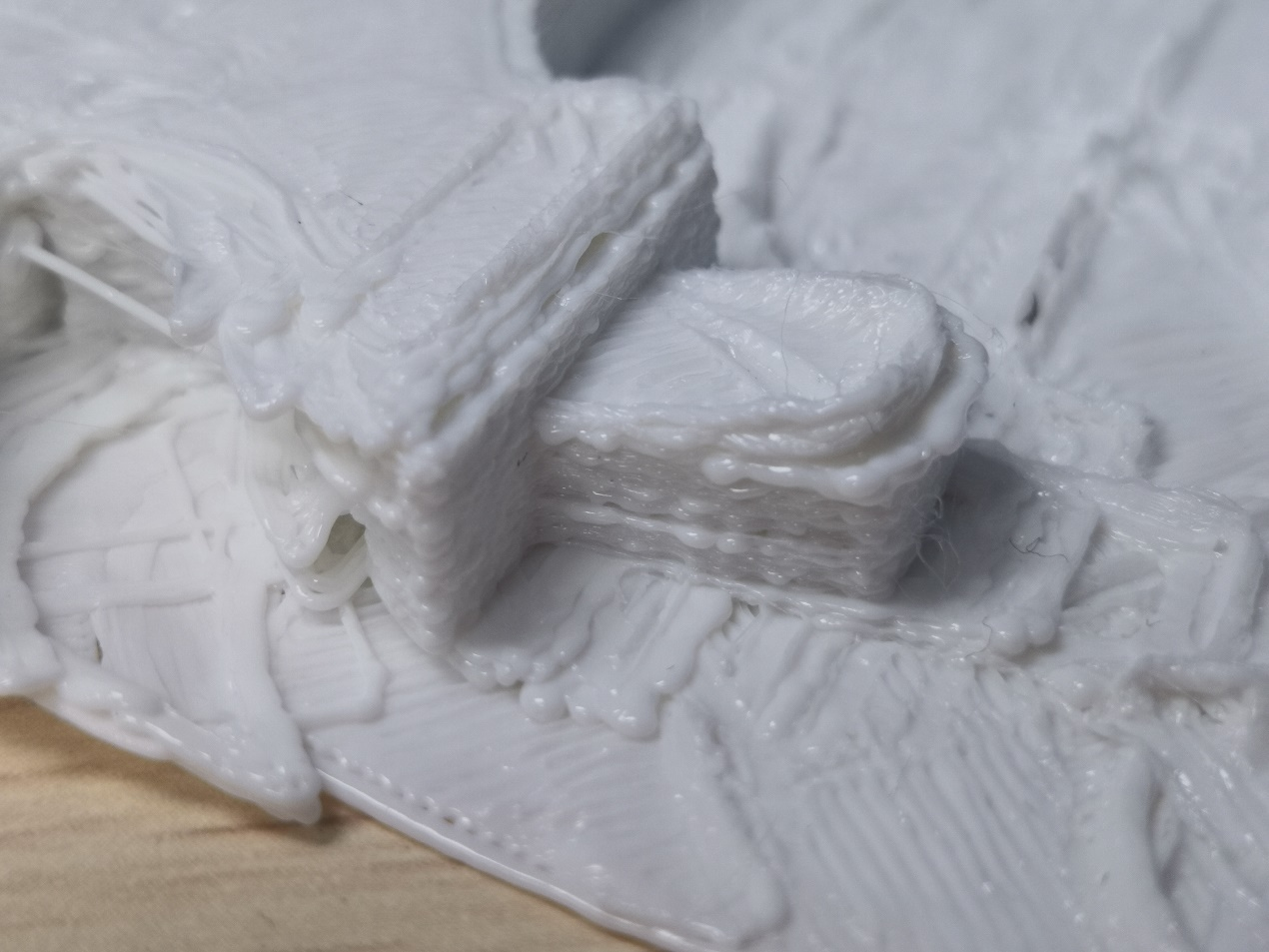

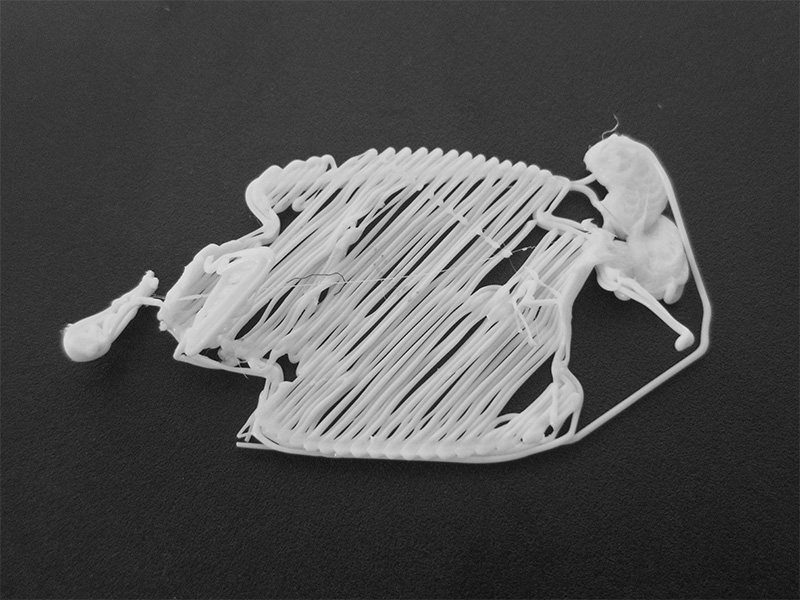

Stringing

WHAT’S THE ISSUE? When the nozzle moves over open areas between different printing parts, some filament oozes out and produces strings. Sometimes, the model will cover strings like a spider web. POSSIBLE CAUSES ∙ Extrusion While Travel Move ∙ Nozzle Not Clean ∙ Filament Quility TROUBLE...MORE -

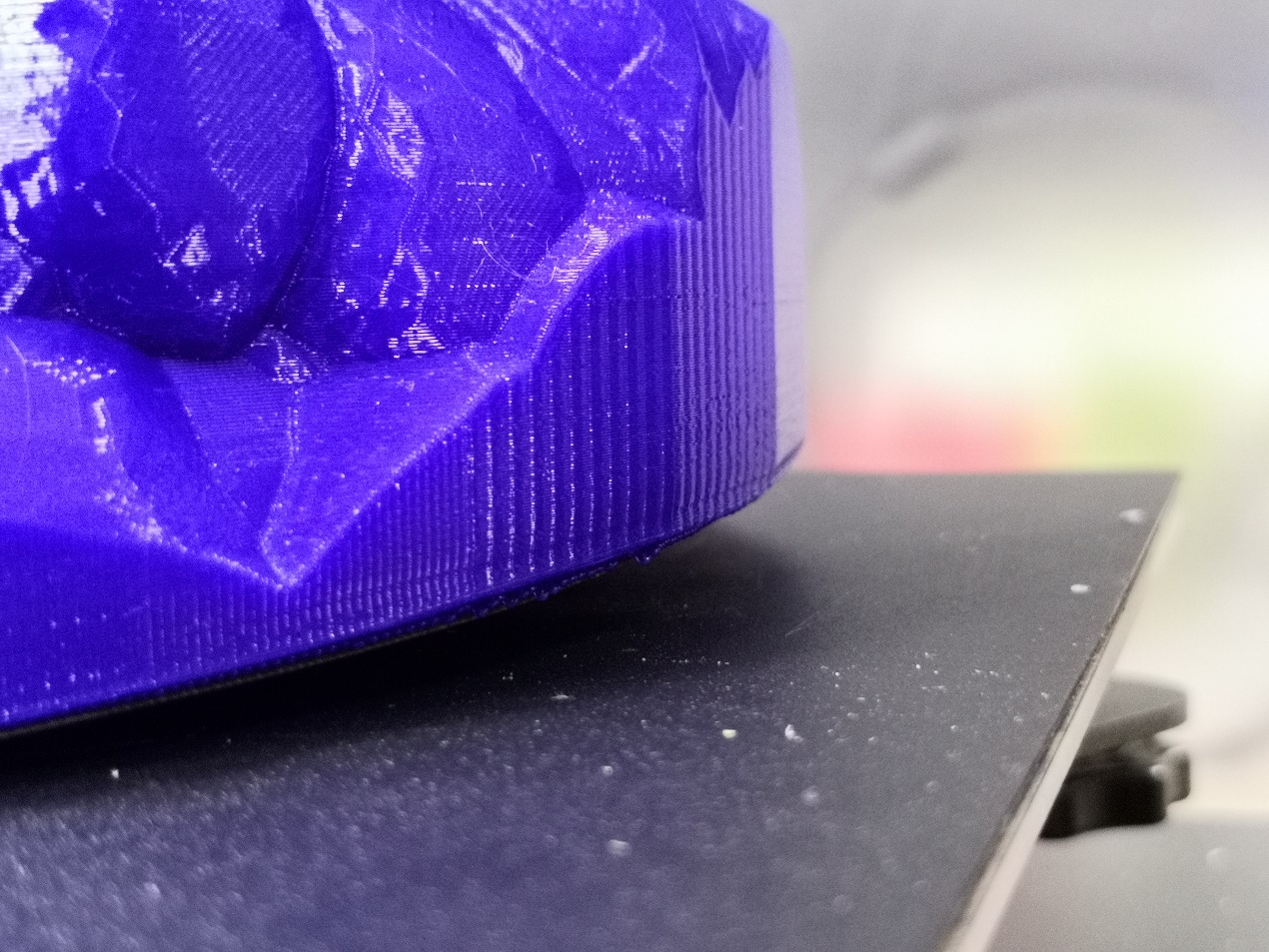

Elephant’s Foot

WHAT’S THE ISSUE? “Elephant feet” refers to the deformation of the bottom layer of the model that slightly protrudes outward, making the model look as clumsy as elephant feet. POSSIBLE CAUSES ∙ Insufficient Cooling on Bottom Layers ∙ Unlevel Print Bed TROUBLESHOOTING TIPS Ins...MORE -

Warping

WHAT’S THE ISSUE? The bottom or upper edge of the model is warped and deformed during printing; the bottom no longer sticks to the printing table. The warped edge may also cause the upper part of the model to break, or the model may be completely separated from the printing table due to poor adhe...MORE -

Overheating

WHAT’S THE ISSUE? Due to the thermoplastic character for the filament, the material become soft after heating. But if the temperature of the newly extruded filament is too high without being rapidly cooled and solidified, the model will easily deform during the cooling process. POSSIBLE CA...MORE -

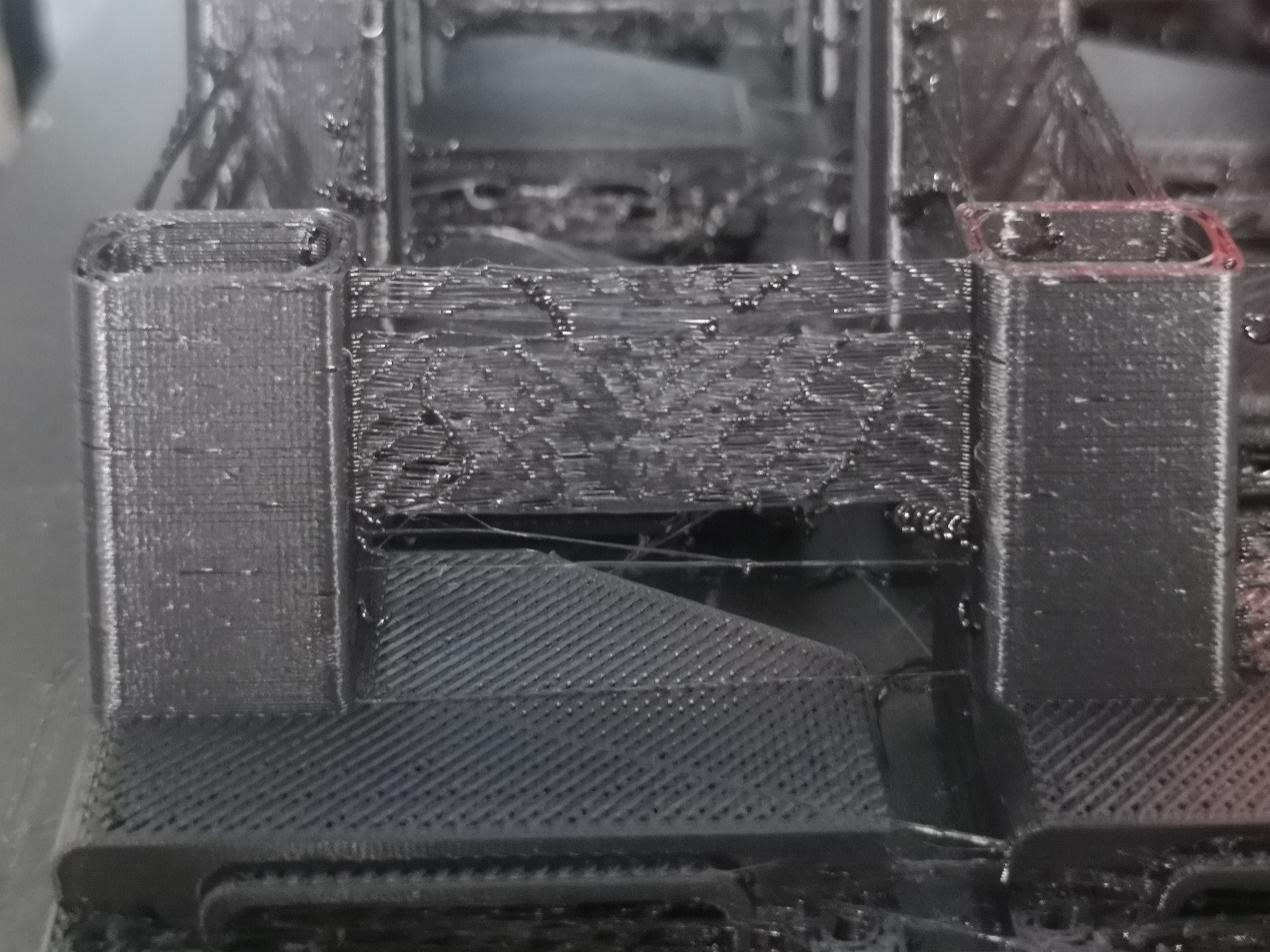

Over-Extrusion

WHAT’S THE ISSUE? Over-extrusion means that the printer extrudes more filament than needed. This causes excess filament accumulate on the outside of the model which make the print in-refined and the surface is not smooth. POSSIBLE CAUSES ∙ Nozzle Diameter Not Match ∙ Filament Diameter Not Mat...MORE -

Under-Extrusion

WHAT’S THE ISSUE? Under-extrusion is that the printer is not supplying sufficient filament for the print. It may cause some defects like thin layers, unwanted gaps or missing layers. POSSIBLE CAUSES ∙ Nozzle Jammed ∙ Nozzle Diameter Not Match ∙ Filament Diameter Not Match ∙ Extrusion Setting No...MORE -

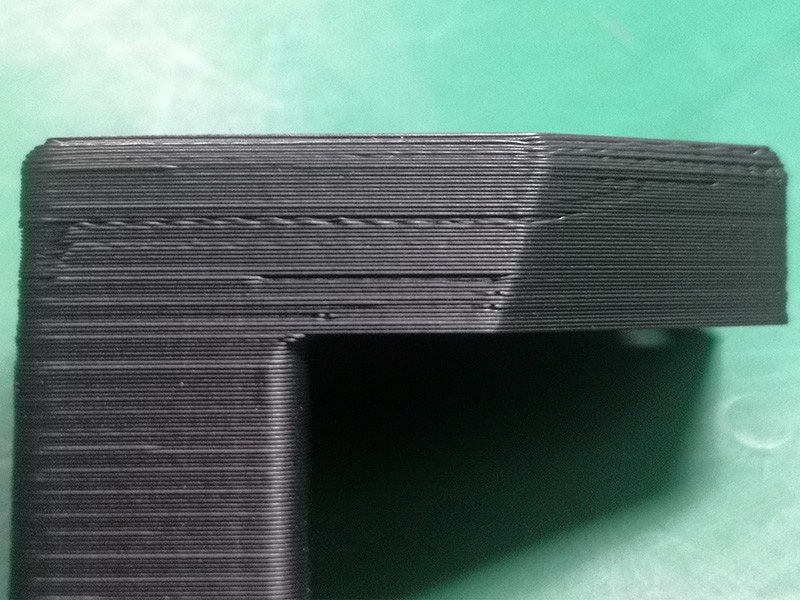

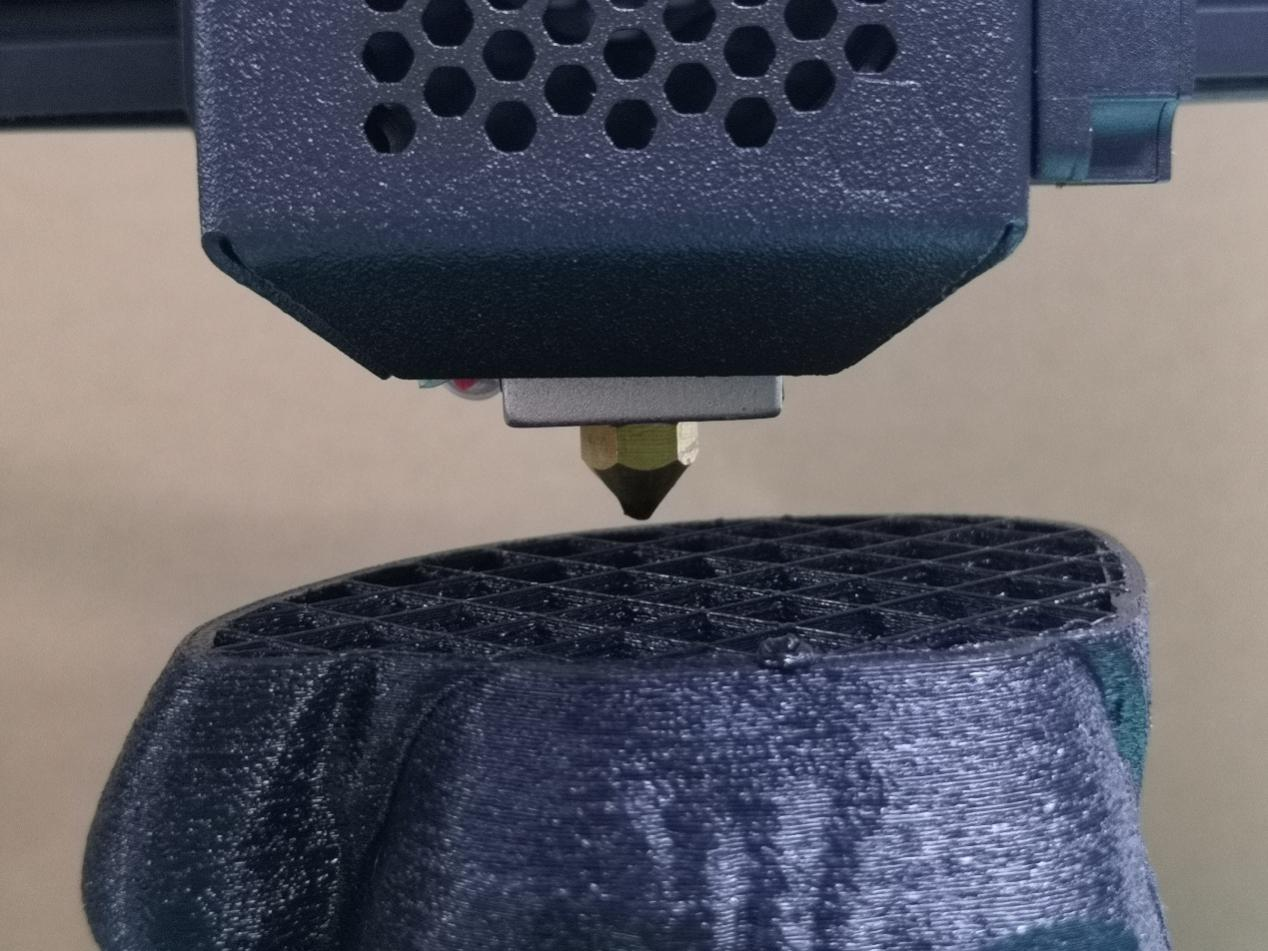

Inconsistent Extrusion

WHAT’S THE ISSUE? A good printing requires continuous extrusion of filament, especially for accurate parts. If the extrusion varies, it will affect the final print quality such as irregular surfaces. POSSIBLE CAUSES ∙ Filament Stuck or Tangled ∙ Nozzle Jammed ∙ Grinding Filament ∙ Incorrect Sof...MORE -

Not Sticking

WHAT’S THE ISSUE? A 3D print should be sticked to the print bed while printing, or it would become a mess. The problem is common on the first layer, but still can happen in mid-print. POSSIBLE CAUSES ∙ Nozzle Too High ∙ Unlevel Print Bed ∙ Weak Bonding Surface ∙ Print Too Fast ∙ Heated Bed Temp...MORE -

Not Printing

WHAT’S THE ISSUE? The nozzle is moving, but no filament is depositing on the print bed at the beginning of the printing, or no filament comes out in mid-print that result in printing failure. POSSIBLE CAUSES ∙ Nozzle Too Close to Print Bed ∙ Nozzle Not Prime ∙ Out of Filament ∙ Nozzle Jammed ∙...MORE -

Grinding Filament

What’s the Issue? Grinding or Stripped filament can happen at any point of the printing, and with any filament. It may cause printing stops, printing nothing in mid-print or other issues. Possible Causes ∙ Not Feeding ∙ Tangled Filament ∙ Nozzle Jammed ∙ High Retract Speed ∙ Printing Too Fast ∙ E...MORE -

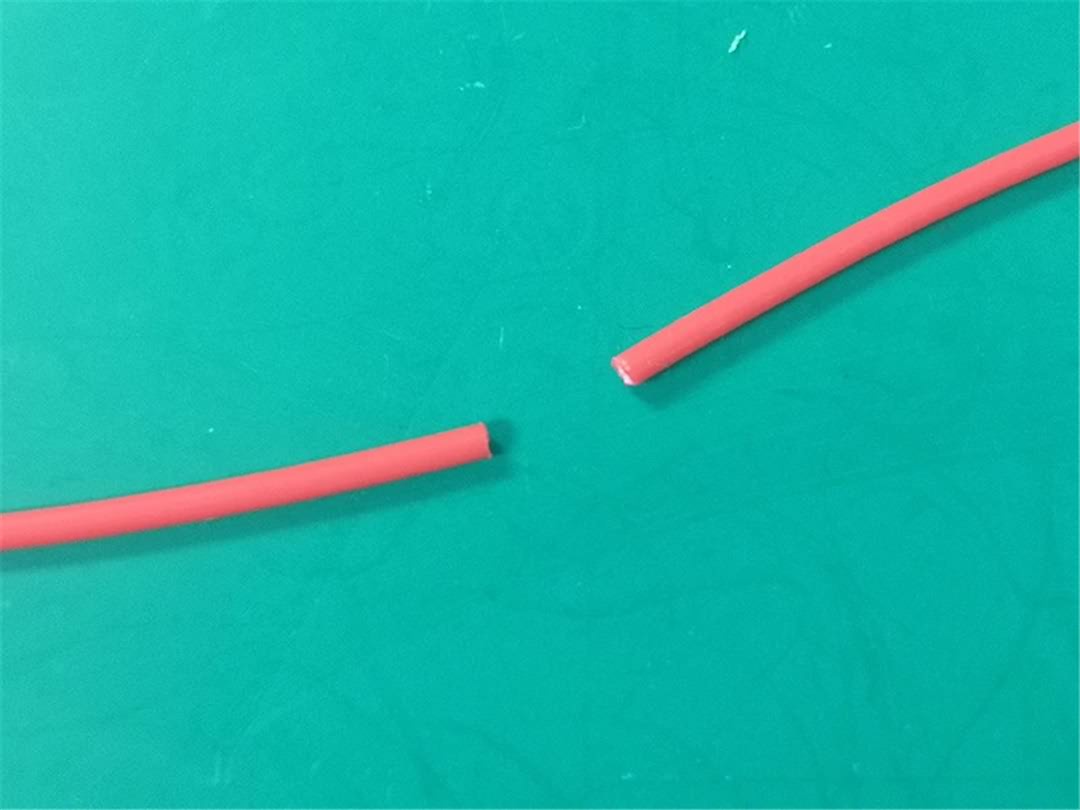

Snapped Filament

What’s the Issue? Snapping can happen at the beginning of the printing or in the middle. It will cause printing stops, printing nothing in mid-print or other issues. Possible Causes ∙ Old or Cheap Filament ∙ Extruder Tension ∙ Nozzle Jammed Troubleshooting Tips Old or Cheap Filament Gener...MORE -

Nozzle Jammed

What’s the Issue? Filament has been fed to nozzle and the extruder is working, but no plastic comes out of the nozzle. Reracting and refeeding doesn’t work. Then it is likely that the nozzle is jammed. Possible Causes ∙ Nozzle Temperature ∙ Old Filament Left Inside ∙ Nozzle Not Clean Trou...MORE