CHII NYAYA?

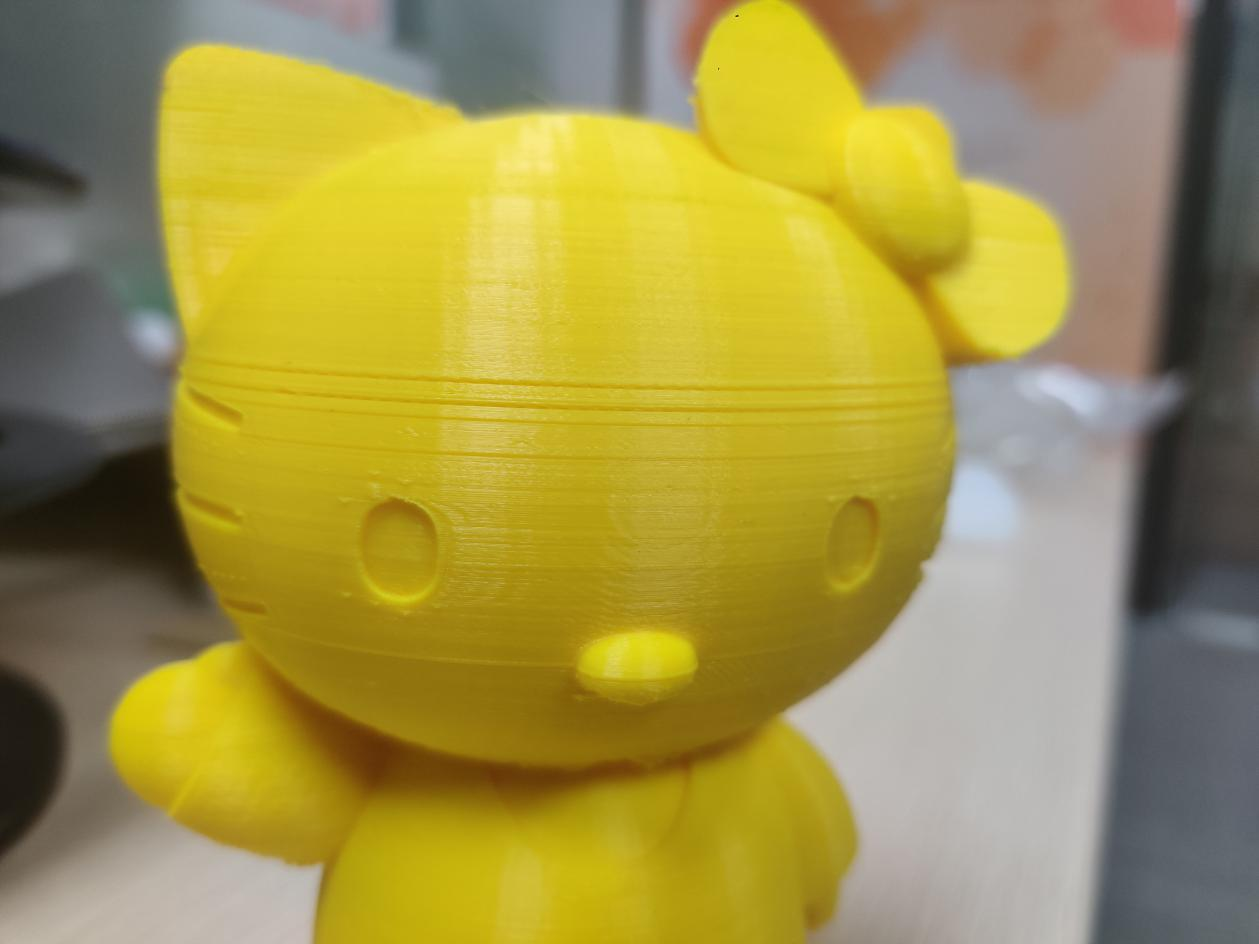

Panguva yekudhinda, mamwe akaturikidzana akadzikwa zvishoma kana zvachose, saka pane mapundu pamusoro peiyo modhi.

ZVINOGONA ZVINOGONA

∙ Tangazve kudhinda

∙ Under-Extrusion

∙ Printer Kurasika Kurongeka

∙ Vatyairi Kupisa

DAMBUDZIKO MATIP

Retaura zvakadhindwa

3D kudhinda idanho rakatetepa, uye chero kumbomira kana kukanganisa kunogona kukonzera kumwe kukanganisa pakudhinda.Kana iwe ukatangazve kudhinda mushure mekumbomira kana kupera simba, izvi zvinogona kuita kuti modhi ishaye mamwe maseru.

Dzivisa kumbomira panguva yekudhinda

Iva nechokwadi chokuti filament yakakwana uye magetsi akagadzikana panguva yekudhinda kudzivirira Kuvhiringidza kudhinda.

Under-Extrusion

Pasi pe extrusion zvinokonzeresa kukanganisa senge kushaikwa kwekuzadza uye kusabatana kwakashata, pamwe nekushaikwa kwezvikamu kubva pamuenzaniso.

UNDER-EXTRUSION

Enda kuUnder-Extrusionchikamu kuti uwane rumwe ruzivo rwekugadzirisa dambudziko iri.

Printer Kurasika Kurongeka

Kukwenya kuchaita kuti mubhedha wekudhinda umire kwekanguva uye tsvimbo yakatwasuka haikwanise kunyatsoenderana nemabhengi emutsetse.Kana paine chero deformation, tsvina kana mafuta akawandisa ane Z-axis tsvimbo uye kubereka, printer inorasika kurongeka uye kukonzera layer isipo.

Spool inobata kukanganisa neZ-axis

Sezvo spool inobata yeakawanda maprinta akaiswa pane gantry, iyo Z axis inomira huremu hwefilament pane inobata.Izvi zvinokanganisa mafambiro nezve Z mota zvakanyanya kana kushoma kukanganisa.Saka usashandise filaments inorema zvakanyanya.

ROD ALIGNMENT CHECK

Tarisa matanda uye ita shuwa kuti pane hukama hwakasimba pakati pematanda nekubatanidza.Uye kuiswa kweT-nut hakusi kusununguka uye hakutadzisi kutenderera kwematanda.

Tarisa matemo ESE

Ita shuwa kuti ese maaxes akagadziriswa uye haana kusuduruka.Izvi zvinogona kutongwa nekudzima simba kana kuvhura iyo stepper mota, wobva wafambisa X axis uye Y axis zvishoma.Kana paine kupikiswa kwekufamba, panogona kunge paine dambudziko nemasanhu.Zvinowanzo kuve nyore kuona kana paine matambudziko nekusarongeka, tsvimbo yakakombama, kana bhegi rakakuvadzwa.

AKAPAKA KUTAURA

Kana bearing racho rapfekwa, ruzha rwekutinhira rwunoitwa kana uchifamba.Panguva imwecheteyo, unogona kunzwa kuti muromo haufambe zvakanaka kana kuita seuri kubvunda zvishoma.Iwe unogona kuona iyo yakatyoka fani nekufambisa muromo uye kudhinda mubhedha mushure mekusunungura simba kana kuvhura stepper mota.

ONA MAFUTA

Izvo zvakakosha kuti uchengete zvese zvakazorwa munzvimbo kuti mushini ushande zvakanaka.Mafuta ekuzora ndiyo yakanakisa sarudzo nekuti yakachipa uye iri nyore kutenga.Pamberi pekuzora, ndapota chenesa njanji netsvimbo dzeakisi imwe neimwe kuti uone kuti hapana tsvina uye filament tsvina pamusoro.Mushure mekuchenesa, ingo wedzera mafuta akatetepa, wobva washandisa muromo kuti uende mberi nekudzoka kuti uone kuti njanji netsvimbo zvakafukidzwa nemafuta uye zvinogona kufamba zvakanaka.Kana ukashandisa mafuta akawandisa, ingopukuta mamwe nemucheka.

Vatyairi Kupisa

Nekuda kwezvimwe zvikonzero senge tembiricha yepamusoro yenzvimbo yekushanda, nguva yakareba inoramba ichishanda, kana mhando yebatch, mota yemutyairi chip yeprinta inogona kupisa.Mune ino mamiriro, iyo chip ichamisa kudzivirira kwekupisa kuvharisa mota dhiraivha munguva pfupi, zvichikonzera kuti zvidimbu zvishaikwe kubva pamuenzaniso.

Wedzera Kutonhora

Wedzera mafeni, masingi ekupisa kana kupisa-kubvisa glue iyo mutyairi chip kudzikisa tembiricha yekushanda yemutyairi chip uye kudzivirira kupisa.

Deredza injini drive ikozvino

Kana iwe uchigona kugadzirisa kana printa yakavhurika sosi, unogona kuderedza ikozvino inofambiswa nekugadzirisa marongero eprinta.Semuenzaniso, tsvaga kuvhiya uku mumenyu "Maintenance -> Yepamberi -> Movement Settings -> Z Yazvino".

Tsiva mainboard

Kana iyo mota ichipisa zvakanyanya, panogona kunge paine nyaya ne mainboard.Zvinokurudzirwa kubata basa revatengi kutsiva mainboard.

Nguva yekutumira: Zvita-29-2020