KGANG KE ENG?

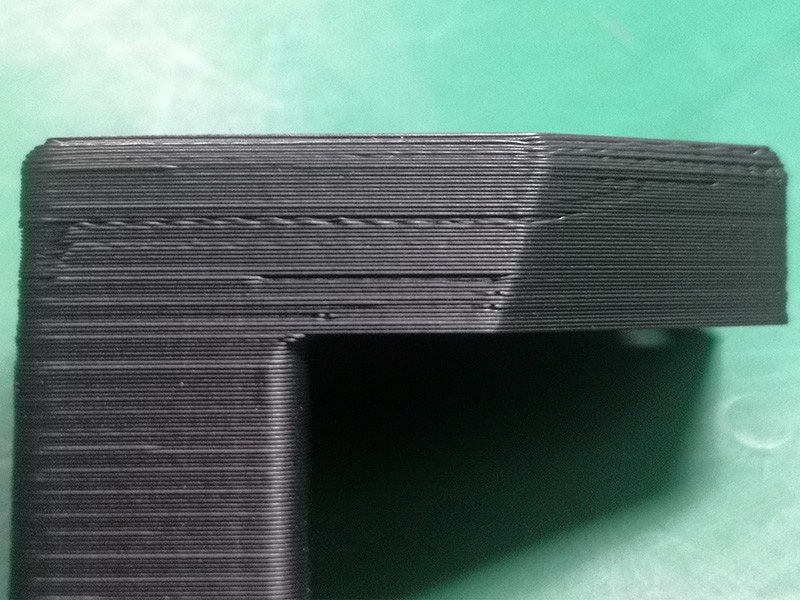

Ho hatisa hantle ho hloka extrusion e tsoelang pele ea filament, haholo-holo bakeng sa likarolo tse nepahetseng.Haeba extrusion e fapana, e tla ama boleng ba ho qetela ba khatiso joalo ka libaka tse sa tloaelehang.

LEBAKA LEBAKA

∙ Filament e Khomaretse kapa e Tangled

∙ Nozzle e Koahetse

∙ Ho sila Filament

∙ Litlhophiso tse Fosahetseng tsa Software

∙ Filament ea khale kapa e theko e tlaase

∙ Mathata a Extruder

LIEKETSENG MATHATA

Filament e khomaretsoe kapa e Tangled

Filament e lokela ho feta hole ho tloha spool ho ea ho nozzle, joalo ka extruder le tube ea ho fepa.Haeba filament e khomaretsoe kapa e ferekanngoa, extrusion e tla fetoha e sa tsitsang.

NTHABISENG FILA

Hlahloba hore na khoele e khomaretsoe kapa e tsitsitse, 'me u etse bonnete ba hore spool e khona ho potoloha ka bolokolohi e le hore khoele e be bonolo ho tsoa ho spool ntle le khanyetso e ngata.

SEBELISA LEQEPHA LE MAHLOKO

Haeba khoele e entsoe ka makhethe ho spool, e khona ho lokoloha habonolo le ka mokhoa o fokolang oa ho ferekanngoa.

HLOKOMELA TUBE FEPE

Bakeng sa li-printer tsa Bowden drive, filament e lokela ho tsamaisoa ka tube ea phepelo.Hlahloba ho etsa bonnete ba hore filament e ka tsamaea habonolo ka har'a tube ntle le ho hanyetsa haholo.Haeba ho na le khanyetso e ngata haholo ka har'a tube, leka ho hloekisa tšupu kapa ho sebelisa lubrication.Hape hlahloba hore na bophara ba tube bo loketse filament.E kholo haholo kapa e nyane haholo e ka lebisa ho sephetho se sebe sa khatiso.

Nozzle e Jammed

Haeba nozzle e tletse ka mokhoa o itseng, filament e ke ke ea khona ho tsoa hantle 'me e fetoha e sa tsitsang.

Eya hoNozzle e Jammedkarolo bakeng sa lintlha tse ling tsa ho rarolla bothata bona.

Gho fafatsa Filament

Extruder sebelisa lisebelisoa tsa ho khanna ho fepa filament.Leha ho le joalo, ho thata ho tšoara giar holim'a khoele e silang, e le hore khoele e be thata hore e ntšoe ka mokhoa o tsitsitseng.

Eya hoHo sila Filamentkarolo bakeng sa lintlha tse ling tsa ho rarolla bothata bona.

ISetlhophiso se nepahetseng sa Software

Litlhophiso tsa software ea slicing li laola extruder le nozzle.Haeba tlhophiso e sa nepahala, e tla ama boleng ba khatiso.

bophahamo ba lera SETTING

Haeba bophahamo ba lera bo ntse bo le nyane haholo, mohlala 0.01mm.Joale ho na le sebaka se senyenyane haholo sa hore filament e tsoe ka molomong 'me extrusion e tla fetoha e sa tsitsang.Leka ho beha bophahamo bo loketseng joalo ka 0.1mm ho bona hore na bothata boa fela.

bophara ba extrusion SETTING

Haeba sebopeho sa bophara ba extrusion se le ka tlase ho bophara ba nozzle, mohlala, bophara ba 0.2mm extrusion bakeng sa nozzle ea 0.4mm, extruder e ke ke ea khona ho sutumelletsa phallo e tsitsitseng ea khoele.E le molao o akaretsang oa monoana, bophara ba extrusion bo lokela ho ba ka hare ho 100-150% ea bophara ba nozzle.

Filament ea khale kapa e theko e tlaase

Filament ea khale e ka nka mongobo moeeng kapa ea senyeha ha nako e ntse e ea.Sena se tla etsa hore boleng ba khatiso bo fokotsehe.Filament ea boleng bo tlaase e ka 'na ea e-ba le li-additives tse eketsehileng tse amang ho tsitsa ha filament.

FETOHA NTSHA

Haeba bothata bo etsahala ha u sebelisa filament ea khale kapa e theko e tlaase, leka spool ea likhoele tse ncha le tsa boleng bo holimo ho bona hore na bothata bo fela.

Mathata a Extruder

Litaba tsa Extruder li ka baka ka ho toba extrusion e sa tsitsang.Haeba lisebelisoa tsa koloi tsa extruder li sa khone ho tšoara khoele ka thata ka ho lekaneng, khoele e ka 'na ea thella' me ea se ke ea sisinyeha joalokaha ho nahanoa.

Fetola tsitsipano ea extruder

Lekola hore na sets'oants'o sa extruder se hlephileng haholo 'me u lokise tensioner ho etsa bonnete ba hore gear ea koloi e tšoara filament ka thata ho lekana.

HLOKOMELA MOKHANTSI

Haeba e le ka lebaka la ho roala ha lisebelisoa tsa koloi hore filament e ke ke ea tšoaroa hantle, fetola mochine o mocha oa koloi.

Nako ea poso: Dec-20-2020